The power of twin shafts

The mechanical shredding of waste is a tough job, so electrical drive systems for shredders must be especially sturdy and reliable. This also applies to the geared motors from WEG’s subsidiary Watt Drive, which the Austrian recycling machinery manufacturer Wagner Shredder uses to drive its new twin-shaft shredder.

For more than 30 years, Wagner Shredder has been developing and producing high-quality recycling machinery in Neuhaus am Klausenbach in Austria. For the development of the new WTS500 universal twin-shaft shredder on request of a customer, Wagner entrusted the implementation of the drive systems to their long-time partner Watt Drive, located in Markt Piesting, Austria.

The WTS500 can be used for cost-effective shredding of all sorts of industrial waste, sheet metal and plastic waste, special waste, metal swarf, electronic scrap, biological waste, wood, glass, and even liquid-filled containers. The material to be shredded is pulled between two shafts rotating slowly in opposite directions, each fitted with cutter discs. The process is monitored by a PLC controller. If the machine is overloaded or foreign objects get into the cutting mechanism, the controller reverses the rotation. A top-mounted stripping comb holds down the shredded material and prevents it from winding around the shafts.

|

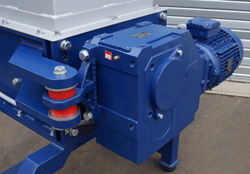

| Figure 1: Wagner uses geared motors from Watt Drive to drive their new WTS500 twin-shaft shredder |

Each of the two shafts in the WTS500 shredder is driven by a sturdy geared motor consisting of a Watt helical bevel gear unit (type KSA 86A) and a WEG four-pole modular motor with frame size 112 or 132. The motors are rated at 4 or 5.5 kW and designed for an operating voltage of 400 or 690 V at 50 Hz. They comply with IP55 protection rating and insulation class F. For overload protection, the motors are equipped with thermal protection. With an output torque of 2,745 Nm and a reduction ratio of 81.14, the geared motors run at output speeds of 18 and 20 rpm respectively.

These relatively low speeds result in gentle shredding of the material with low levels of wear, dust generation and noise emission. There’s a good reason for running the two geared motors at different speeds and driving the two shredder shafts of the WTS500 in opposite directions: in this way the shafts do a better job at pulling in the material to be shredded. For protection against the harsh operating conditions, the geared motors are also equipped with protection-caps for hollow shafts, torque arms and rubber buffer kits.

|

| Figure 2: The two independent drives in the WTS500 provide uniform torque on the two shafts |

Wagner also relies on drive solutions from Watt Drive for its perforators. They are used to slit or puncture PET bottles and containers with capacities up to five litres. Slitting or puncturing makes the pressed bales more compact and denser.

One or two ASA 76A shaft-mounted geared motors from Watt Drive are used in the perforators, depending on the model. They are equipped with WEG modular motors with rated power of 2.2 or 5.5 kW and essentially the same basic specifications as the shredder drives. However, they differ from the geared motors for the WTS500 in terms of output torque (470 Nm) and reduction ratio (17.73), resulting in a significantly higher output speed of 81 rpm. The perforator drives are additionally equipped with a special hollow shaft.