The New Modular Motor

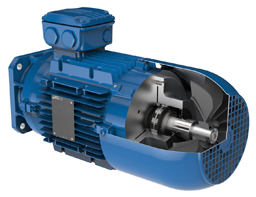

Watt Drive is anxious to achieve highest modularity in its products. Through close cooperation of the development teams, a new system motor will be created that unites the high WEG quality requirements with the unique modular system of Watt Drive. The new motor generation can be offered as minimum efficiency class IE2 as well as IE3 and it can be combined with efficient Watt gears and thus be designed as an energy saving and environment-sparing drive system.

The completion of the new product lines is planned in the 1. quarter 2013.

Features:

- EUSAS® winding

- Efficiency class IE2, IE3

- Modular system

The EUSAS® motor (Europe - USA - ASia)

The strong points of the new modular motor are not only preserved but also enhanced. With the specialised 12-strand design of the motors, high voltage flexibility can be achieved by switching to up to four different voltage levels (Y/D, YY/DD). Additionally an enhanced frequency inverter operation (100Hz, 120 Hz, constant torque) can be realised. With frequency inverster operation, the rated motor power even doubles. Furthermore through the patented WISE® isolation system of WEG motors the durability of the stators is increased as well, when operating with frequency inverters.

Modular System

The motors have been especially designed for the assembly of various motor modules so that the flexibility rises and a quick delivery is guaranteed. On customers’ requirement the motor modules can be mounted singly or in combination.

Some of the most important mechanical motor mountings:

- Spring loaded brakes

- Encoder systems

- Forced cooling

- Backstops

- Alternative connection technique

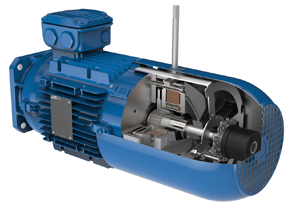

Picture 1: Self ventilated modular motor with spring-loaded brake, manual release and incremental encoder

Spring loaded brake

Robust rectifier spring loaded brakes with 24 VDC, 230 VAC or 400 VAC ensure the proper brake power.

Optionally obtainable:

- Rust protected, dust protected

- Noise-damped

- With manual release, locking device

- Micro switch, fast-excitation rectifier

- Double brake, heavy duty (IP66) brake

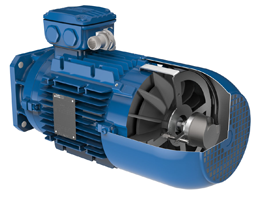

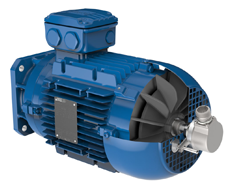

Encoder systems

Various encoders can be mounted within or outside the fan cover.

- Incremental encoder (TTL, HTL)

- Absolute encoder with SSI interface

- Resolver, DC tacho

- Optionally with separate encoder terminal box.

Picture 2: Modular motor with incremental encoder within the fan cover

Picture 3: Modular motor with incremental encoder outside the fan cover

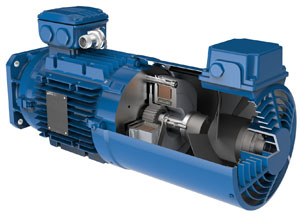

Forced cooling

The ventilation is obtainable as single-phase, three-phase and with wide voltage range.

Picture 4: Modular motor with spring loaded brake, encoder and ventilation

Backstop

The very robust built backstops prevent e.g. return movement of the conveyor material on upward conveying machinery.

Picture 5: Modular motor with backstop

Alternative connection technique:

- MIP multi pin box

- MIG connect plug-in system

The MIP box can be equipped with up to 22 terminals and one brake rectifier. All options of the Watt motor system like brake, encoder system etc. can be realised in only one terminal box.

Picture 6: Modular motor with multi pin box

Advantages:

- A lot of space in the terminal box

- Easy connection

- Neatly wiring

The MultI pluG (MIG) connect is a decentral standardised connection variant that Watt Drive uses for the integration of power- and operation wiring of motor modules in just one plug.

Picture 7: Modular motor with MIG connect plug-in system

Advantages:

- Mounting and exchange of motors with minimal personnel expenditure

- Prevention of wiring failures while exchanging electric motors

- Downtimes are shortened and the costs of production losses are considerably reduced.

Further information about the WATT motor system can be found under the following Link: Motor System